State-of-the-art production facility with modern equipment and clean room environments.

Cutting-edge machinery and precision manufacturing processes.

Scalable production capabilities to meet global demand.

Hanyoo – Professional Pharmaceutical Equipment Manufacturer in China

Jiangsu Hanyoo Pharmatech Co.Ltd. is a high technology enterprise which has strong research, production, sales and after-service team.

We are specialized in providing the professional packaging solution and packaging equipment for pharmaceutical, medical instruments, cosmetics and electronics industrials.

Our over 20 years pharmaceutical machinery experience can help you more on building your intelligent factory.

Hanyoo factory is located in Nanjing city, which occupied more than 12,000 square meters. The main products are capsule filling machine, tablet press machine, blister packing machines, capsule/tablet counting machine, granulator, coating machine, mixing machine etc. We have over hundred of inventions patented technology, with leading R&D team, with a variety of high-precision processing equipment and quality testing team to provide product quality assurance. The company passed ISO9001:2016 quality management certification, the products passed through the EU CE certification.

End-to-End Pharmaceutical Machinery Solutions for Your Production Lifecycle

We deliver more than just high-quality machinery and provide a comprehensive partnership. From initial custom design and precision manufacturing to seamless on-site integration and reliable long-term support, we are committed to maximizing your operational efficiency at every stage.

- Custom R&D and Precision Manufacturing Our expert engineers collaborate with you to develop tailored equipment (e.g., capsule fillers, bottle packing lines) that meet your specific product requirements and strict GMP standards.

- Professional Installation and Commissioning Our skilled technical teams provide global on-site installation, rigorous testing, and seamless integration into your existing facility, ensuring optimal performance from day one.

- Responsive After-Sales and Maintenance Service We guarantee maximum uptime with dedicated lifecycle support, including rapid technical troubleshooting, readily available spare parts, and preventive maintenance programs.

Production Lines & Equipment Types

High-speed rotary tablet press machines for efficient pharmaceutical production with precise compression control.

Automatic capsule filling equipment with high accuracy and production capacity for pharmaceutical applications.

Advanced blister packaging machines for tablets and capsules with automated feeding and sealing.

High-efficiency powder mixing and blending machines for uniform pharmaceutical formulations.

Wet and dry granulation equipment for pharmaceutical powder processing with precise control.

Professional tablet coating equipment, suitable for food applications such as film coating and sugar coating.

Efficient drying equipment for pharmaceutical granules with uniform heat distribution.

Fully integrated pharmaceutical production lines from mixing to packaging with automation.

The SL-2A Semi-Automatic Counting Machine is a high-tech drug counting equipment.

Custom Solutions Available

Our experienced engineering team can develop customized equipment solutions tailored to your specific production requirements and industry needs.

Complete equipment solutions for solid dosage manufacturing including tablets, capsules,etc.

Specialized equipment for food supplement manufacturing and packaging with GMP compliance.

Equipment for cosmetic powder processing and solid product manufacturing with precision control.

Why Hanyoo is Trusted by 1000+ Clients

Our products sold to more than 30 provinces in China and exported to over than 100 countries in the world, and we won good reputation and credibility.

State-of-the-art production facility with modern equipment and clean room environments.

European Conformity & ISO9001 certification for product safety and compliance.

R&D, production, sales, and service – all under one roof.

Cutting-edge machinery and precision manufacturing processes.

Field Installation and Commissioning

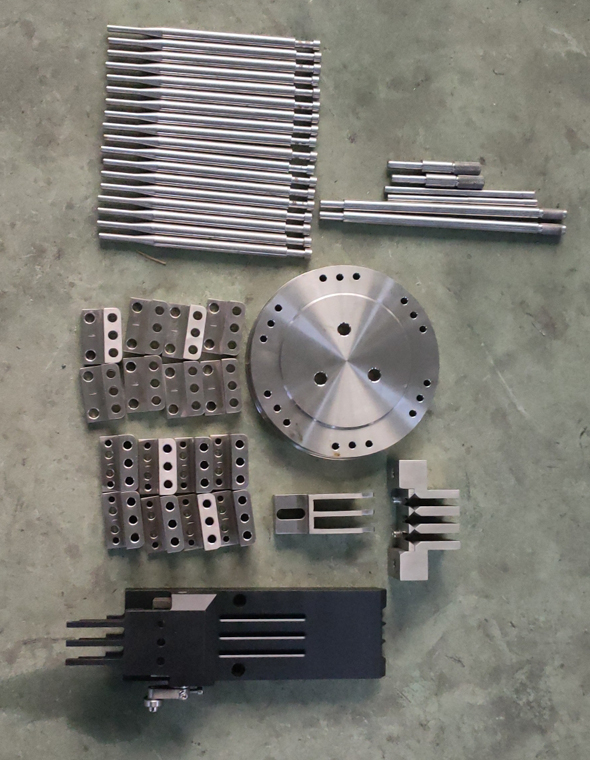

Advanced CNC machining ensures microscopic precision, delivering flawless solid dosage for superior mechanical stability.

- Mirror Polished Finish

- Argon Arc Welding

- 316L Stainless Steel

- GMP Compliant Design

- Dead-Zone Free

- Precision Laser Cutting

- Dynamic Balance Test

- Seamless Welding Joint

Equipment Production Process

Create premium, leak-proof sachets with high-speed precision, ensuring product freshness and brand appeal.

- Servo Motor Drive

- PLC Smart Control

- PID Temp Control

- Nitrogen Gas Flush

- Auto Pouch Feeding

- Zipper Opening System

- Safety Guard Protection

- Vacuum Suction Pickup

Custom Solutions Available

Our experienced engineering team can develop customized equipment solutions tailored to your specific production requirements and industry needs.

We strategically utilize AISI 304 stainless steel for the machine's exterior housing and non-contact frames, ensuring structural stability and a sleek, professional finish that resists impact and daily wear. However, for critical areas—specifically those in direct contact with pharmaceutical powders and tablets—we exclusively employ superior 316L stainless steel.

This low-carbon, molybdenum-alloyed grade offers exceptional resistance to corrosion and pitting, making it impervious to reactive chemical agents and harsh sterilization processes. By integrating these specific alloy grades, Hanyoo ensures full compliance with international cGMP standards. When you choose Hanyoo, you are investing in machinery that offers not just mechanical precision, but the lasting reliability of the world's finest steel.

- Production Capability 24/7 hours

- Max Capsules/Hour 456,000 pcs/h

- Loading Accuracy 99.99%

- Dosage Precision ±3-5% accuracy

- Capsule Loading Rate >99.99%

- Noise Level <75dB

Our Equipment Applications

- Tablet Manufacturing

- Capsule Production

- Powder Processing

- Granulation Systems

- Coating Operations

- Blister Packaging

- Bottle Packaging

- Turnkey Projects

- Automation control

What Our Customer Say

“Our DPP-360E has been running continuously for 18 months with minimal maintenance.”

Karlfrom Thailand

Karlfrom Thailand“They are very passionate in every fabrication process and guided me throughout the production.”

Lailafrom U.K

Lailafrom U.K“Hanyoo's equipment quality is world-class.Hanyoo's technical team was comprehensive and professional.”

Markfrom Hongkong

Markfrom Hongkong“Hanyoo developed a specialized solution for our unique tablet pressing requirements, highly efficient.

Lailafrom U.K

Lailafrom U.K